Your Trusted Chinese EV Charger Manufacturers

ZinstarEV is one of the leading Chinese EV Charger manufacturers, factory and supplier. At ZinstarEV, we are your go-to source for high-performance AC EV Chargers solutions ,EV Adapters, EV Extension Cables. Whether you prefer our ready-made specifications or wish to customize your own, our Top Quality EV Chargers are designed to excel in diverse applications. Choose ZinstarEV to take your projects to new heights.

Table Of Contents For This Page

It is not easy to introduce all aspects of EV Chargers, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

Discover Our Garanteed EV Chargers

Market-Ready Solutions | Quality Meets Innovation | Customer Satisfaction

ZS01 3.5kW 8A-16A Adjustable Portable EV Charger-Single Phase

TOP1 HOT SELLING For Retailers And Wholesales

- Customization Plug

- Adjustable Current 8A-16A

- Plug Lighting + Current Switching

- Mordern Car Shape Design

- IP67

- IK10

- Full Protection

- EV Standard: IEC 62752, IEC 61851

ZS02 8A-32A 7kW Adjustable AC EV Charger-Single Phase

Fast And Reliable Charging, 5 Mode Adjustment

- Customization Plug

- 5 Mode Adjustable Current 10A-32A

- LED Screen Display

- Delayed Charging + Current Switching

- IP67

- IK10

- Full Protection

- EV Standard: IEC 62752, IEC 61851, NB/T 42077-2016

ZS03-32A Mode2 7kW AC EV Charger-Single Phase

Cost-Friendly And Easy Operation

- Customization Plug

- Adjustable Current 10A-32A

- LED Screen Display

- Delayed Charging + Current Switching

- IP67

- IK10

- Full Protection

- EV Standard: IEC 62752, IEC 61851

ZS04-16A Pro 3.5kW Portable EV Charger-Single Phase

Durable Pro Design With Steady Performance

- Customization Plug

- Output Current 16A/ 32A

- LED Screen Display

- Delayed Charging

- IP67

- IK10

- Full Protection

- EV Standard: IEC 62752, IEC 61851

ZS05-40A New SMART 11kW AC EV Charger-Single Phase

Auto-Detect & Terminal Secure Lock: Minimize SKUs, Maximize Safety

- Customization Plug

- Output Current 16A/ 40A

- Terminal lock design-anti drop when charging

- Terminal design cable reduce stocking SKU

- Terminal auto-detect current design prevent over current charging

- Delayed Charging

- IP67

- IK10

- EV Standard: IEC 62752, IEC 61851

ZS06 2.5kW 7kW ECO Portable EV Charger

SUPER-ECO

- Customization Plug

- SKU1-Fixed Output Rated Current 16A 3.5kW

- SKU2-Fixed Output Rated Current 32A 7kW

- LED Charging Indicator

- Multiple-Protection design

- Delayed Charging

- IP Waterproof

- IK10

- EV Standard: IEC 62752, IEC 61851

ZS07 11kW 22kW 5 Pin Portable EV Charger-Three Phase

Super Fast Portable Charging with 5 Pin

- Customization Plug

- SKU1-16A 11kW

- SKU2-32A 22kW

- LCD display Screen

- Multiple-Protection design

- Delayed Charging

- IP Waterproof

- IK10

- EV Standard: IEC 62752, IEC 61851

ZS-WB01- 7/ 11/ 22 kW AC EV Charging Station Wall Mounted Charger

Home & Commercial Use Wall Mounted EV Charging Station

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- SKU Option-7/ 11/ 22kW

- RFID/ APP control

- OCPP1.6J

- Multiple-Protection design

- Wall mounted/ stand option

- IP65

- IK10

ZS-WB02- 7/ 11/ 22 kW AC EV Charging Station Wall Mounted Charger

Home & Commercial Use Wall Mounted EV Charging Station

- GBT/ Type1/ Type2 Charging Gun Available

- SKU Option-7/ 11/ 22kW

- RFID/ APP control

- OCPP1.6J

- Multiple-Protection design

- Wall mounted/ stand option

- IP65

- IK10

- White/ Black color option

ZS-WB05- 7/ 11/ 22 kW AC EV Charger Wall Box Bluetooth/Wifi APP control

Home Use AC EV Charging Station

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- SKU Option-7/ 11/ 22kW

- RFID/ APP control

- OCPP1.6J Supported

- Multiple-Protection design

- Wall mounted/ stand option

- IP55

- IK10

- White/ Red color option

7/ 11/ 22 kW AC EV Charger Wall Box

Residential Use Plastic Housing- EACB

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- Output Power: 7/ 11/ 22kW

- Plug in & Charge/ RFID/ APP

- OCPP1.6J Supported

- Multiple-Protection design

- IP55

- IK10

- Wall mounted/ floor stand accessory option

- 4G Module/ Wifi & Bluetooth Module option available

7/ 11/ 22 kW AC EV Charger Wall Box

Commercial Use Metal Housing EACB

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- Output Power: 7/ 11/ 22kW

- Plug in & Charge/ RFID/ APP

- OCPP1.6J Supported

- Multiple-Protection design

- IP55

- IK10

- Wall mounted/ floor stand accessory option

- 4G Module/ Wifi & Bluetooth Module option available

7*2 / 11*2 / 22*2 kW AC EV Charger Wall Box Dual Gun

Commercial Use Metal Housing EACB

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- Output Power: 14/ 22/ 44kW

- Plug in & Charge/ RFID/ APP

- OCPP1.6J Supported

- Multiple-Protection design

- IP55

- IK10

- Wall mounted/ floor stand accessory option

- 4G Module/ Wifi & Bluetooth Module option available

7 / 11 / 22 kW AC EV Charger Floor Stand Single Gun

Commercial Use Metal Housing-ACL

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- Output Power: 7/ 11/ 22kW

- Plug in & Charge/ RFID/ APP

- OCPP1.6J Supported

- Multiple-Protection design

- IP55

- IK10

- Floor Stand

- 4G Module/ Wifi & Bluetooth Module option available

7*2 / 11*2 / 22*2 kW AC EV Charger Floor Stand Single Gun

Commercial Use Metal Housing-ACL

- GBT/ Type1/ Type2/ Tesla Charging Gun Available

- Output Power: 14/ 22/ 44kW

- Plug in & Charge/ RFID/ APP

- OCPP1.6J Supported

- Multiple-Protection design

- IP55

- IK10

- Floor Stand

- 4G Module/ Wifi & Bluetooth Module option available

Comprehensive AC EV Charger Video Showcase: Production, Testing & Innovation

Discover how your business can benefit from our comprehensive AC EV charger solutions. With videos showcasing our state-of-the-art production lines, rigorous testing processes, and product highlights, you’ll gain confidence in partnering with us. Whether you’re seeking custom-built chargers or high-quality standard models, we have the capacity and innovation to meet your needs. Start building the future of electric mobility with a reliable manufacturing partner today.

See Your Charging Solutions Come to Life: AC EV Charger Wall Box Production Line

Take an exclusive look at your future EV charging products being built in ZinstarEV’s production lines. This video offers you a detailed walkthrough of customized and standard AC EV chargers undergoing rigorous testing, ensuring every product meets the highest standards of safety, durability, and performance. Imagine these premium chargers powering your business’s success. Partner with us and experience how our capacity and commitment to quality can meet your specific project needs effortlessly.

Streamline Your EV Charger Supply: AC & Portable EV Charger Manufacturing

At ZinstarEV, we understand your business needs flexibility and scalability in EV charging solutions. In this video, you’ll see two of our high-capacity production lines in action. The first focuses on portable EV chargers and wall boxes, while the second dives deeper into AC EV Charger wall boxes, showcasing semi-finished products and rigorous testing processes. This is where precision meets reliability, ensuring every charger meets the highest standards. Whether you’re looking for standard models or customized solutions, we’re ready to support your growth. Contact us today to see how we can power your business forward!

Wanna dig deeper in EV Charger?

There are many more information in this report, you can leave us you email here and our experienced Expert will contact with you within 24 hours.

The ODM Regular Process Flow & Duration Estimation

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

Let's talk about Your EV Needs!

Reach out to ZinstarEV with your EV charger requirements via email, phone, or our website. Our team will provide detailed product information, pricing, and answer any questions you may have to ensure our solutions match your needs perfectly.

Upon request, we can provide samples of our EV chargers for you to test and evaluate. This step ensures our product meets your standards for quality and compatibility with your specific applications.

After receiving the samples, thoroughly test and evaluate them to ensure they meet your exact specifications and performance standards. Your feedback is crucial for any adjustments or final approval before mass production.

Once the samples are approved, and you’re ready to proceed, we’ll finalize the order details. The next step is to complete the payment for the mass production order, securing your inventory and initiating the manufacturing process.

Once you place your order, we’ll begin the manufacturing process. Our team ensures every charger is made to our high standards, undergoing rigorous quality checks to guarantee they meet your requirements and industry certifications.

After production and quality confirmation, your order will be securely packed and shipped by air or by sea. We’ll provide you with the tracking information and support you through customs clearance to ensure a smooth delivery to your location. requirements and industry certifications.

How to Customize EV Chargers?

Customizing an EV charger involves several steps, from initial design considerations to final product certification. This process allows for the creation of a charger that meets specific requirements, such as charging speed, connector type, smart features, and more. Here’s a comprehensive guide to customizing an EV charger.

Start by clearly defining the specific requirements for the charger. This includes the desired charging speed, connector types (e.g., SAE J1772, CCS, CHAdeMO), smart features (such as app connectivity, remote monitoring, scheduling), and any physical design preferences.

Decide whether the charger will provide AC or DC charging. Level 2 chargers typically offer AC charging, but some applications might benefit from DC charging capabilities for faster charging speeds monitoring, scheduling), and any physical design preferences.

Engage in the design and development process, focusing on the electrical circuit design, enclosure design, and user interface. Ensure the design adheres to safety standards and is user-friendly. For example, for Level 1 EV chargers, the design should be compatible with standard 120-volt AC outlets

Upon agreeing on the design and specifications, ZinstarEV will develop a prototype of the custom EV charger. This step is crucial for visualizing the final product and making any necessary adjustments before mass production.

The prototype will be sent to you for testing and evaluation. This period allows you to provide feedback on the design, functionality, and any other aspects that may need refinement.

After adjusting the prototype based on your feedback, we seek your final approval on the design to ensure it completely aligns with your requirements.

With the design approved, we commence the tooling process, creating molds and tools necessary for manufacturing the custom EV chargers. All the tooling process are under control and will test with T1,T2 samples during the process.

Conduct thorough testing of both the hardware and software components. This includes safety testing, performance testing, and user testing to ensure the charger meets all specified requirements and operates reliably under various conditions

Obtain necessary certifications to ensure compliance with industry standards and regulations. This may include certifications for safety, electromagnetic compatibility (EMC), and specific automotive or electrical standards relevant to the target markets

Design the packaging and user manual, focusing on providing clear instructions for installation, use, and maintenance. The packaging should protect the charger during shipping and handling, while the manual should enhance the user experience

Produce a sample or a small batch of the chargers for further testing and validation. This step helps confirm the mass production capability and allows for any necessary adjustments before full-scale production

Upon your approval of the sample and small batch test, we proceed with the bulk production of your custom OEM EV chargers, ensuring each unit adheres to the agreed specifications and quality standards.

Want to make your OWN Brand EV Charger?

All You Need to Know About EV Chargers

Welcome to the world of EV charging! As a top AC Charger manufacturer from China, ZinstarEV is here to guide you through everything you need to know about EV chargers. With the rise of electric vehicles, understanding how to charge them efficiently and safely is crucial. Whether you’re new to electric vehicles or looking to expand your knowledge, this guide will provide you with clear and concise information to help you navigate the EV charging landscape.

CHAPTER 1

What is an EV Charger?

An Electric Vehicle (EV) charger, also known as an EV charging station, is a device that provides electrical power to recharge electric vehicles, including battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and others. EV chargers are an essential component of the electric vehicle ecosystem, enabling owners to charge their vehicles at home, at work, or at public charging stations.

CHAPTER 2

Types of EV Chargers

Level 1 Chargers

- Connection: Standard 120V outlet (North America) or 230V outlet (Europe and other regions).

- Charge Speed: Approximately 5 km (3 miles) per hour of charging.

- Average Time to Full Charge: 20 hours or more, depending on the vehicle’s battery capacity.

- Installation and Infrastructure: Can be plugged into standard household outlets without the need for additional installation or infrastructure, making them a convenient choice for residential use.

- Use Case: Best suited for overnight charging at home or emergency use due to its slow charging speed.

- Connector Type: Commonly uses the SAE J1772 connector in North America and other connectors depending on the region.

Level 2 Chargers

- Connection: 240V outlet in North America, 230V in Europe and other regions.

- Charge Speed: 30–50 km (20–30 miles) per hour of charging.

- Average Time to Full Charge: 6 to 14 hours, making it suitable for home, workplace, and public charging stations.

- Installation and Infrastructure: Require a 240V outlet and may necessitate professional installation and electrical upgrades. They are suitable for home, workplace, and public charging stations.

- Use Case: Ideal for daily use, offering a faster charging speed compared to Level 1 chargers. Commonly found in public areas and residential complexes.

- Connector Type: SAE J1772 is standard in North America, with the IEC 62196 Type 2 connector being common in Europe.

DC Fast Charging (Level 3)

- Connection: Direct current (DC) connection bypassing standard electrical outlets.

- Charge Speed: Up to 200 km (124 miles) per hour of charging, with some chargers offering even faster speeds.

- Average Time to Full Charge: 20 minutes to an hour, depending on the vehicle’s battery capacity and the charger’s maximum output.

- Installation and Infrastructure: Require high-voltage supply (400V to 900V) and are significantly more expensive, making them less common in residential settings. They are primarily installed in public locations like highways and commercial areas.

- Use Case: Designed for quick charging during long-distance travel. Commonly located along major highways and thoroughfares.

- Connector Type: Includes the Combined Charging System (CCS) for North America and Europe, CHAdeMO for Japanese vehicles, and the Tesla Supercharger for Tesla vehicles. The North American Charging Standard (NACS) is also emerging as a universal option.

CHAPTER 3

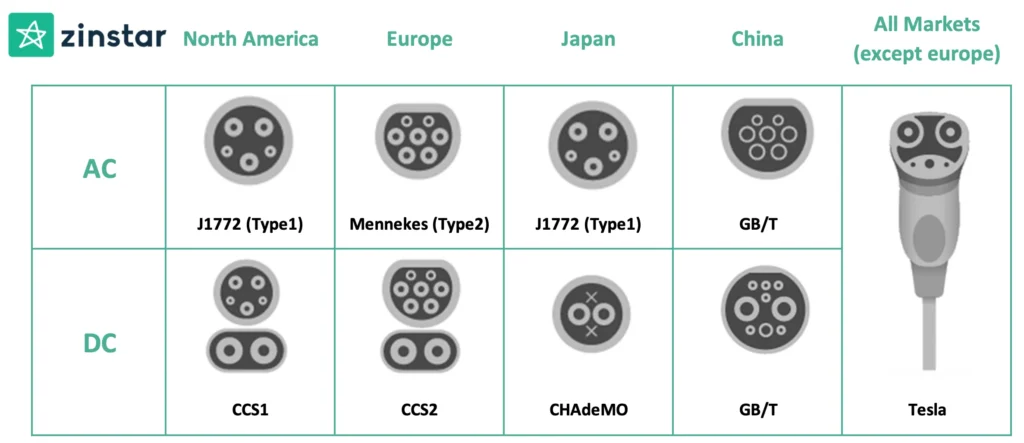

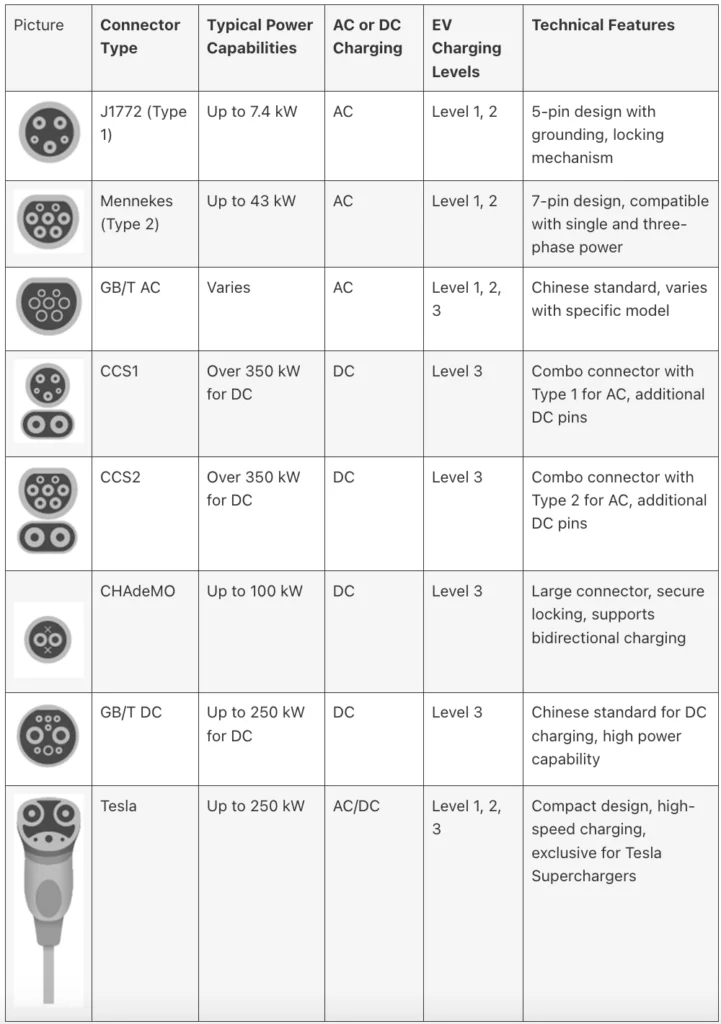

Connectors of EV Chargers

- SAE J1772 (Type 1): Used primarily in North America and Japan for Level 1 and Level 2 charging.

- IEC 62196 Type 2 (Mennekes): The standard connector in Europe for Level 2 charging, supporting up to 22 kW of power.

- Combined Charging System (CCS): A DC fast charging connector used in North America and Europe.

- CHAdeMO: A DC fast charging connector developed by the Tokyo Electric Power Company, popular in Japanese EV markets.

- Tesla Connector: Used exclusively by Tesla vehicles, with adapters available for other connector types

GB/T: China’s national standard for EV charging, including both AC and DC charging connectors.

CHAPTER 4

How EV Charger works?

Electric Vehicle (EV) chargers work by pulling electrical current from a power source and delivering it to the EV’s battery, similar to how various devices are charged by plugging them into a wall outlet. The process involves several key components and steps to ensure the safe and efficient transfer of electricity from the grid to the vehicle. Here’s an insight into the technical mechanics behind EV charging:

- Power Source: The charger is connected to a power source, which can be a standard 240v outlet for Level 2 chargers or a direct connection to the electrical grid for some installations. This connection provides the electrical current needed for charging.

- Electricity Conversion: Depending on the type of charger and vehicle, the electricity drawn from the power source may need to be converted from alternating current (AC) to direct current (DC) before it can be used to charge the vehicle’s battery. Level 1 and Level 2 chargers typically deliver AC power to the vehicle, where an onboard converter changes it to DC for battery storage. DC fast chargers, on the other hand, convert the power to DC externally before delivering it to the vehicle, allowing for much faster charging times.

- Communication Protocol: When an EV is connected to a charger, a communication protocol is established between the vehicle and the charging station. This protocol ensures compatibility and safety, allowing the vehicle to communicate its current state of charge and maximum charging rate. The charger then adjusts the power output accordingly to optimize charging speed and protect the vehicle’s battery.

- Charging Process: Once the connection is made and communication is established, the charger begins delivering power to the vehicle’s battery. The rate at which the battery charges depends on several factors, including the power output of the charger (measured in kilowatts, kW), the capacity of the vehicle’s battery, and the current state of charge. Level 2 chargers, for example, can provide a maximum output of around 7.7 kW, significantly reducing charging times compared to Level 1 chargers, which use a standard 120-volt outlet.

- Safety Features: EV chargers are equipped with various safety features to protect both the vehicle and the user. These include mechanisms to detect and prevent electrical faults, ensure proper grounding, and automatically stop charging if a problem is detected or when the battery reaches full capacity.

- End of Charging: Once the vehicle’s battery is fully charged, the charger automatically stops delivering power. The vehicle and charger may also communicate to adjust the charging rate as the battery approaches full capacity, ensuring a safe and efficient charging process.

CHAPTER 5

What's Key Features of EV Chargers

Safety Features

- Overcurrent Protection: This feature prevents the flow of excessive current that could potentially harm the electric vehicle, the charger, or the electrical installation. It ensures the charging process stops if current exceeds a safe level.

- Temperature Control: Our chargers are equipped with temperature sensors to monitor and regulate heat. If temperatures rise above safe levels, the system automatically reduces the charging current or temporarily halts charging to prevent overheating.

- Ground Fault Protection: To protect against electrical faults that could lead to electric shocks, our chargers include ground fault circuit interrupters (GFCIs) that quickly disconnect power if a fault is detected.

Smart Charging Capabilities

- Wi-Fi and Bluetooth Connectivity: ZinstarEV chargers can connect to home or public Wi-Fi networks and Bluetooth, allowing users to monitor and control the charging process remotely via a smartphone app. This includes scheduling charging times to take advantage of lower electricity rates.

- App Integration: Our dedicated app provides real-time data on charging status, history, and energy consumption. Users can also receive notifications for complete charges or reminders to start charging.

Environmental Resistance

- Weatherproofing: Designed for durability, our chargers are built to withstand harsh weather conditions, including rain, snow, and extreme temperatures. This makes them suitable for both indoor and outdoor installations.

- Material Durability: The casings of our chargers are made from high-grade, UV-resistant materials that prevent fading and cracking, ensuring the charger maintains its integrity and appearance over time.

CHAPTER 6

How to Install EV Chargers

Residential EV Charger Installation

Step 1: Determine the Type of Charger

- Level 1 Charging: Utilizes a standard 120V AC outlet. Suitable for overnight charging and typically does not require any special installation.

- Level 2 Charging: Requires a 240V AC supply. Offers faster charging and usually necessitates professional installation.

Step 2: Assess Electrical Capacity

- Evaluate your home’s current electrical system to ensure it can support the additional load of an EV charger. This may involve consulting with a licensed electrician.

Step 3: Obtain Necessary Permits

- Many jurisdictions require a permit for installing an EV charger. Check with your local building department or permitting agency for specific requirements.

Step 4: Choose a Qualified Electrician

- Select a local electrical contractor with experience in EVSE installation. This ensures adherence to all safety standards and local regulations.

Step 5: Installation

- Follow the manufacturer’s instructions for mounting the charger and making electrical connections. Ensure that the installation complies with the National Electrical Code (NEC) and local building codes.

Step 6: Final Inspection

- Once installed, a final inspection by a local building inspector may be required to ensure the installation meets all safety and code requirements.

Commercial EV Charger Installation

Step 1: Planning and Consultation

- Commercial installations often require more planning due to the complexity of the installation site and the intended use of the chargers. Consult with the permitting and/or planning agency early in the process.

Step 2: Assess Electrical Infrastructure

- Determine if the existing electrical infrastructure can support the EV chargers or if upgrades are necessary. This may involve significant electrical work.

Step 3: Obtain Permits

- Similar to residential installations, commercial EV charger installations require permits. The specific requirements can vary widely, so it’s important to consult with local authorities.

Step 4: Professional Installation

- Due to the complexity of commercial installations, it’s crucial to work with contractors who have specific experience with commercial EVSE projects.

Step 5: Compliance and Inspection

- Ensure the installation complies with all relevant codes and standards. A final inspection by local authorities may be required to verify compliance.

Step 6: Maintenance Plan

- Establish a maintenance plan to ensure the chargers remain in good working condition and are safe to use

General Safety and Efficiency Tips

- Use Certified Equipment: Choose EV chargers that are certified by recognized testing laboratories, such as UL or ETL, to ensure safety and reliability.

- Follow Manufacturer’s Instructions: Adhere strictly to the manufacturer’s installation and operation instructions.

- Consider Future Needs: When planning the installation, consider future expansion. Installing additional conduit or electrical capacity now can save time and money later.

- Accessibility: For commercial installations, ensure the chargers are accessible to all users, including those with disabilities.

CHAPTER 7

How to Select the Right EV Charger

Factors to Consider

Charging Speed:

- Determine the charger’s output, measured in kilowatts (kW). A higher kW rating means faster charging. Consider your vehicle’s charging capability and daily driving distance to decide between Level 1, Level 2, or DC Fast Chargers.

Compatibility with Your Vehicle(s):

- Ensure the charger’s connector type matches your vehicle. Most modern EVs use Type 2 connectors in Europe and CCS or CHAdeMO for fast charging, while North America primarily uses the J1772 connector for AC charging.

Installation Location:

- Assess the intended installation site for electrical capacity and environmental conditions. Outdoor chargers should be durable and weather-resistant, while indoor chargers might focus more on aesthetics and noise levels.

User Needs:

- Reflect on who will be using the charger. For personal use, consider your daily routine and whether smart charger features could benefit you. For commercial use, think about customer convenience, such as the need for multiple charging points and ease of payment.

Compatibility with Your Vehicle(s)

- Check the Charger’s Specifications: Ensure the charger you select is fully compatible with your vehicle’s make and model. This includes the charger’s level, connector type, and maximum output.

- Vehicle Manufacturer Recommendations: Many vehicle manufacturers recommend specific types or brands of chargers. Following these recommendations can ensure optimal charging efficiency and battery health.

Comparing Residential, Commercial, and Public Charging Solutions

- Residential Chargers: Ideal for overnight charging at home. Level 1 and Level2 chargers are most common, offering a good balance between charging speed and cost.

- Commercial Chargers: For businesses looking to provide charging for customers or employees, Level 2 and DC Fast Chargers are popular options. Considerations include user fees, charger management systems, and the potential need for multiple charging stations.

- Public Charging Stations: Typically offer Level 2 and DC Fast Charging options. When selecting equipment for public use, durability, ease of use, and compatibility with a wide range of vehicles are key considerations.

CHAPTER 8

What Are the Key Raw Materials of EV Chargers

Metals:

- Copper: Widely used in the conductive parts of the charger, including wiring and electrical contacts, due to its excellent electrical conductivity.

- Aluminum: Often used for the charger’s casing and heat sinks because of its light weight and good heat dissipation properties.

- Steel: Used for structural components and casings for its strength and durability, especially in outdoor and commercial-grade chargers.

Plastics and Polymers:

- Polycarbonate (PC): A durable and heat-resistant plastic used for the housing of many chargers, offering a high degree of safety and longevity.

- Polyethylene (PE): Used in cable insulation for its flexibility and electrical insulation properties.

- Thermoplastic Elastomers (TPEs): Often used for cable sheathing on the charger cord, combining flexibility with durability and resistance to environmental factors.

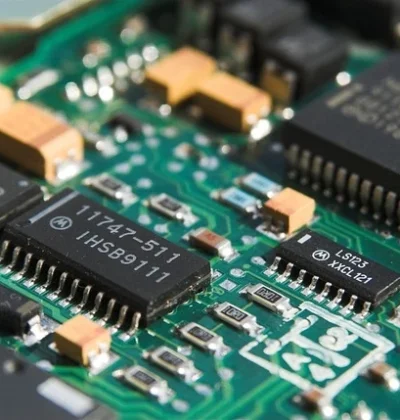

Electronic Components:

- Semiconductors: Key in the control and conversion circuits, they regulate the charging process and ensure compatibility with the vehicle’s battery management system.

- Capacitors and Resistors: Essential for smoothing out electrical currents and maintaining stable operation under various electrical loads.

- Printed Circuit Boards (PCBs): Serve as the backbone for mounting electronic components, designed to fit the compact spaces of modern EV chargers while ensuring efficient electrical pathways.

Impact of Raw Material Quality on Performance and Durability

- Conductivity and Efficiency: The purity of copper used in wiring and contacts affects the charger’s efficiency by minimizing energy loss during transmission.

- Environmental Resistance: Materials like UV-resistant polycarbonate for housings and high-grade TPE for cables ensure the charger can withstand harsh weather conditions, UV exposure, and physical wear and tear.

- Safety: The use of flame-retardant materials and robust electrical insulation protects against overheating, electrical fires, and short circuits, ensuring the charger operates safely under all conditions.

CHAPTER 9

How Are EV Chargers Made?

Design and Engineering

Conceptualization:

- Begins with identifying market needs and technological trends. Our engineers and designers collaborate to conceptualize innovative charging solutions that address these needs.

Technical Design:

- Detailed schematics and blueprints are created, specifying the electrical circuitry, components, and physical structure of the charger. Emphasis is placed on efficiency, safety, and user experience.

Prototyping:

- Early models are built to test the design’s feasibility. These prototypes undergo rigorous testing to evaluate performance, durability, and safety, with results informing further refinements.

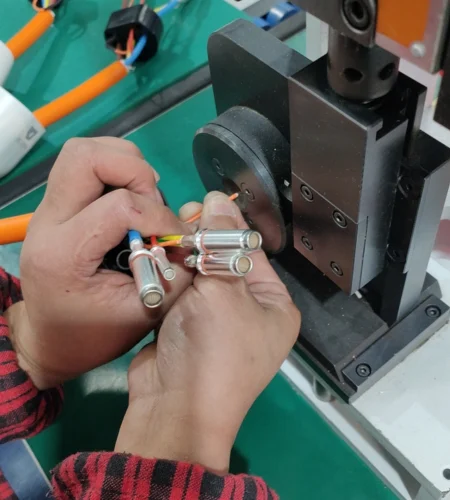

Component Sourcing and Assembly

Sourcing High-Quality Materials:

- We source raw materials and components from trusted suppliers, ensuring they meet our stringent quality standards. This includes high-conductivity metals, durable plastics, and reliable electronic components.

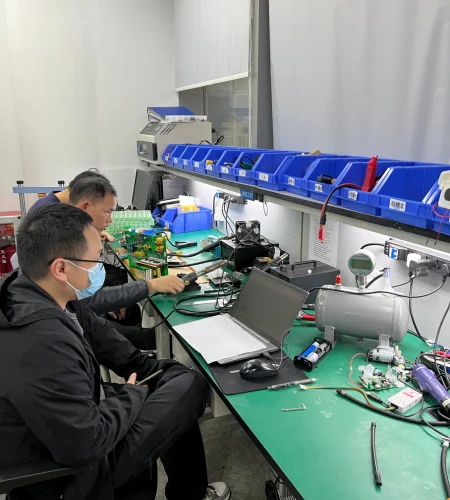

Assembly Line Production:

- Chargers are assembled on sophisticated production lines. Skilled technicians and automated machinery work in concert to accurately assemble and solder components, ensuring consistency and precision in every product.

Integration of Smart Technology:

- For smart chargers, software is integrated into the hardware. This includes programming for Wi-Fi or Bluetooth connectivity, app integration, and advanced charging controls.

Testing and Quality Assurance

Functional Testing:

- Each charger undergoes a series of functional tests to verify it operates correctly across a range of conditions. This includes charging speed, connectivity, and safety features like overcurrent protection.

Environmental and Durability Testing:

- Chargers are exposed to extreme temperatures, humidity, and physical stress to ensure they can withstand real-world environmental conditions.

Certification:

- Final products are tested for compliance with international safety and performance standards, earning certifications that attest to their quality.

Eco-Friendly Packaging:

- Chargers are packaged in materials designed to protect the product while minimizing environmental impact. This packaging is robust enough to ensure safe transportation and delivery.

This production process reflects ZinstarEV’s commitment to excellence at every stage, from the initial design to the final product in the customer’s hands. By adhering to rigorous standards and embracing innovation, we ensure that every ZinstarEV charger delivers unmatched performance, safety, and reliability.

CHAPTER 10

Factors to Consider before Design EV Chargers

User Interface and Experience

- Ease of Use: The charger should feature an intuitive design, making it easy for users of all backgrounds to operate. This includes clear instructions, simple plug-in procedures, and straightforward charging status indicators.

- Accessibility: Design considerations should ensure accessibility for all users, including those with disabilities. This may involve the height of the charging unit, the ease of handling the cable and plug, and the readability of displays and instructions.

Compatibility and Connectivity

- Charger Type and Power Output: The design must cater to the intended use case, whether it’s for slow, overnight charging (Level 1), faster home and public use (Level 2), or rapid charging stations (DC Fast Charging). The power output should match the needs of the majority of vehicles the charger intends to serve.

- Connector Types: Incorporating the most widely used connectors, such as Type 1 (SAE J1772) and Type 2 (IEC 62196), ensures broader compatibility. Consideration of including adapters or swappable cables can also enhance versatility.

- Smart Features: Integration of Wi-Fi or Bluetooth for connectivity with smartphones or networked systems allows for features like remote monitoring, control, and payment, enhancing the user experience.

Safety and Reliability

- Electrical Safety: Designs must include features to protect against overcurrent, short circuits, and ground faults. The use of high-quality, durable materials is essential to prevent overheating and ensure safe operation under all conditions.

- Weatherproofing: Outdoor chargers, in particular, need to be designed to withstand environmental elements—waterproofing, dust resistance, and UV protection are key factors to consider for longevity and reliability.

Aesthetics and Environmental Integration

- Visual Appeal: An attractive design can make the charging station more inviting to users and can also complement the architectural aesthetics of the surrounding environment.

- Space Efficiency: Considering the physical footprint and the way the charger occupies space is crucial, especially in urban or densely populated areas. Chargers should be designed to minimize obstruction while still being easily accessible.

Scalability and Maintenance

- Modular Design: Designing chargers with modular components can simplify maintenance and future upgrades, extending the lifespan of the charger and adapting to evolving technology without requiring complete replacement.

- Ease of Maintenance: Chargers should be designed for easy access to components that may require regular maintenance or replacement, reducing downtime and operational costs.

CHAPTER 11

Factors to Consider before Customization of EV Chargers

Adaptable Charging Standards:

- EV chargers can be customized to support various charging standards, including Type 1 (SAE J1772), Type 2 (IEC 62196), CCS, CHAdeMO, and Tesla. This ensures broad compatibility with a wide range of electric vehicles.

Adjustable Output Levels:

- Customizing the charger to offer adjustable output levels allows users to optimize charging based on their vehicle’s capacity and charging needs, enhancing efficiency and convenience.

Connectivity Options:

- Incorporating Wi-Fi, Bluetooth, or cellular connectivity into chargers enables remote monitoring, control, and firmware updates, making the charging process more convenient and efficient.

Energy Management Systems:

- Customization can include integration with home or building energy management systems, allowing for smart energy consumption, cost savings, and support for renewable energy sources.

Physical Design:

- The physical design of EV chargers can be customized to match the installation environment, whether it’s a private home, commercial property, or public space. This includes considerations for size, color, and form factor.

Branding and Signage:

- Custom branding options allow businesses to incorporate their logos, color schemes, and marketing messages on the chargers, turning them into marketing tools that enhance brand visibility.

CHAPTER 12

How to Select a Reliable EV Charger Manufacturer?

- Expertise: Experience often translates to a deeper understanding of market needs and the technical challenges of producing effective charging solutions.

- Customer Reviews and Testimonials: Customer feedback can provide valuable insights into a manufacturer’s reliability, product quality, and customer service. Look for reviews across various platforms, including industry forums and social media.

- Certifications: Reliable manufacturers ensure their products meet international safety and quality standards. Look for certifications like UL, CE, and RoHS, which indicate compliance with regulatory requirements.

- Warranty and Support: A manufacturer’s confidence in their product quality is often reflected in their warranty terms. Longer warranties and comprehensive support services are indicators of a reliable manufacturer.

- Innovative Solutions: Manufacturers that invest in research and development to offer innovative charging solutions are often more capable of meeting the evolving needs of the EV market.

- Product Variety: A wide product range allows you to choose a charger that fits your specific requirements, whether it’s for residential, commercial, or industrial use.

- Customization Options: The ability to customize products to fit specific needs is a sign of a manufacturer’s flexibility and customer-centric approach. This can include customizable power outputs, connectors, and software integration.

- Scalability: Reliable manufacturers can scale production to meet demand, ensuring timely delivery of products even as your charging needs grow.

- Ethical Manufacturing: Ethical labor practices in the manufacturing process are an important consideration. Look for manufacturers that adhere to international labor standards.

Discover the Future of EV Charging with ZinstarEV TODAY

More Information About EV Charging World

What Is a DC Charging Pile?

Fast EV charging is no longer a luxury — it’s an industry standard. But if you’re sourcing EV infrastructure, you’ve likely heard the term “DC charging pile“ and wondered what exactly it means. In this

What’s the Difference between 7kW AC and 7kW DC Portable EV Charger ?

Lots of customer ask me this question when we send this 7kW AC and DC Portable EV Charger product spec and video to them, so what’s the difference between 7kW AC and 7kW DC portable

Merry Christmas and Happy New Year 2025 !

Dear Friends and Partners, Merry Christmas and Happy New Year 2025! 🎄🎄🎄 🎆 🎆🎆 As the holiday season arrives, we want to take a moment to say a heartfelt thank you. Your trust, support, and

What is 7kW EV Home Charger? Speed, Efficiency, and Practicality Explained

As electric vehicles (EVs) continue to gain popularity, one significant player in this realm is the 7kW EV home charger. This section explores what a 7kW EV home charger is, how it works, and its

EV Adapter Types Guide: Choosing the Right EV Adapter for Compatibility and Optimal Charging

Follow this EV adapter types guide to choose the right one for the electric vehicle (EV) is a crucial step in ensuring efficient charging and maximizing the usability of the EV car. With a variety

ZinstarEV’s 2024 China National Day Holiday Closure Notice

A Heartfelt Thank You to Our Valued Customers and Partners! 🙏 As we prepare for the National Day holiday here in China, the ZinstarEV team would like to take a moment to thank all our

How to Import EV Chargers from China? Ultimate Guide

How to import EV chargers from China? Identify reliable Chinese EV charger manufacturers, offering high-quality, customizable EV Charger products. Ensure the chargers meet international certifications, working with a trusted freight forwarder and avoid common pitfalls.

Happy Mid-Autumn Festival from ZinstarEV!

Dear Valued Partners and Customers, Happy Mid-Autumn Festival ! As the Mid-Autumn Festival approaches, we want to take a moment to express our sincere gratitude for your continued support and partnership throughout the year. This

What is the CCS2 to GBT DC Adapter? Everything You Need to Know

As electric vehicle (EV) adoption rises globally, compatibility between different charging standards becomes crucial. This is where the CCS2 to GBT DC Adapter comes into play. For businesses and consumers navigating these varying standards, understanding

What are the Different Types of EV Chargers?

As the demand for electric vehicles (EVs) continues to rise globally, understanding the different types of EV chargers is crucial for businesses involved in the distribution, retail, and installation of EV charging solutions. As an

The Common Pitfalls When Purchasing

When purchasing EV chargers from suppliers, there are several common pitfalls that buyers should be aware of to ensure they receive quality products and avoid complications. Here are some of the key issues.

- Quality and Safety Concerns

- Supplier Reliability

- Certification and Compliance

- After-Sales Service

- Communication Barriers

- Logistics and Shipping

- Hidden Costs

- Product Consistency

By being aware of these pitfalls and taking steps to mitigate them, such as thorough supplier vetting, insisting on proper documentations, and establishing clear communication and contracts, request samples for testing and approval, buyers can successfully navigate the process of purchasing EV chargers from reliable suppliers, meet the business needs and ensures a successful import process.

A Brief Self-Nomination, Why Choose ZinstarEV?

Your Brand Deserves the Best Manufacturing

Step into ZinstarEV factory operation facility, See for yourself how quality and innovation are embedded in our DNA for every single EV Charger.

Click To See Our Factory

The FAQs About EV Chargers

We offer a wide range of EV chargers, including Level 1, Level 2, available in various configurations to meet your specific needs.

Yes, we offer OEM services allowing you to customize the EV chargers with your brand logo, packaging, and specific technical specifications to align with your brand identity.

The MOQ varies depending on the model and customization requirements. Typically, our MOQ starts at 100 units, but we are flexible and can discuss options to accommodate your needs.

Yes, we offer full logistic support, including arranging shipping via sea, air, or express courier, depending on your preferences. We can also assist with customs clearance to ensure a smooth delivery process.

Quality is our top priority. We conduct rigorous testing and quality checks at every stage of production, from raw materials to final assembly, ensuring each charger meets our high standards and your expectations.

Ready to Transform Your EV Charging Today ?

Discover How Our EVSE Solutions Make a Difference!